February, the month of love, of the flame that burns within us, of passion!

This month, Cristallerie de Montbronn would like to share with you its own passion, which drives its inner fire from day to day: crystal, of course! That's why we're taking you on a journey through the crystal-making process, from birth to rebirth!

The Awakening of Nature

In the eternal dance of the elements, there is a magnificent alchemy where fire and earth come together to create the crystalline splendour that has captivated the human soul since time immemorial.First discovered in the 1670s by English-speaking people, the formula for the composition of crystal was not discovered until a century later in France. At the heart of this process lies the germ of radiant beauty: silica. Like a treasure hidden deep in the earth, silica is extracted in the form of sand, quartz or rock crystals. This is where the journey to transformation begins.

In France, regulations are very strict when it comes to lead and the composition of crystal: a minimum of 24% lead is required for exceptional brilliance and ease of handling. Generally speaking, quality crystal contains around 50% silica, 20% potash and at least 24% lead. As a general rule, quality crystal contains around 50% silica, 20% potash and at least 24% lead.

To find out more about the differences between glass, crystal and crystalline, read the dedicated blog article.

Ritual of Fire

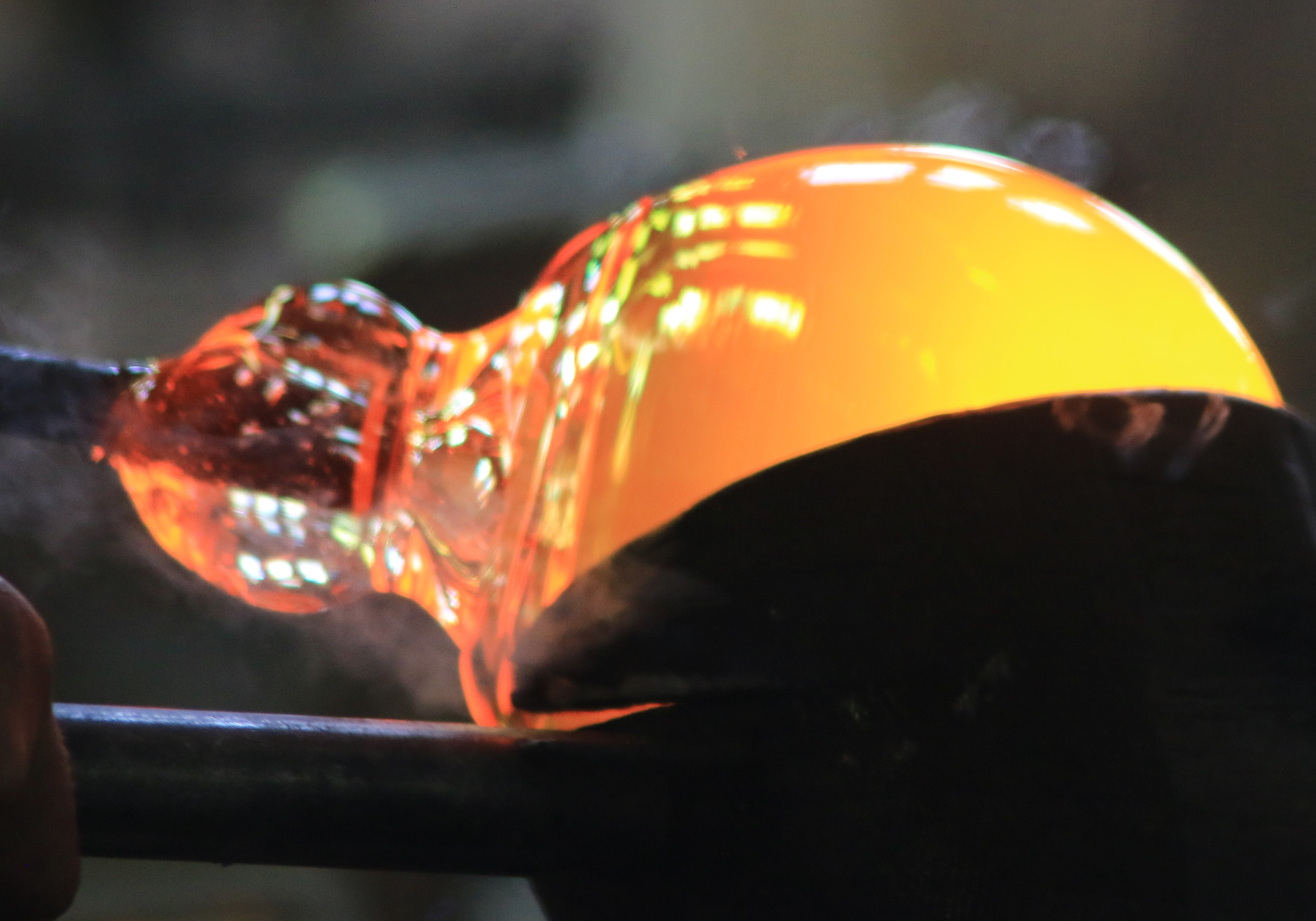

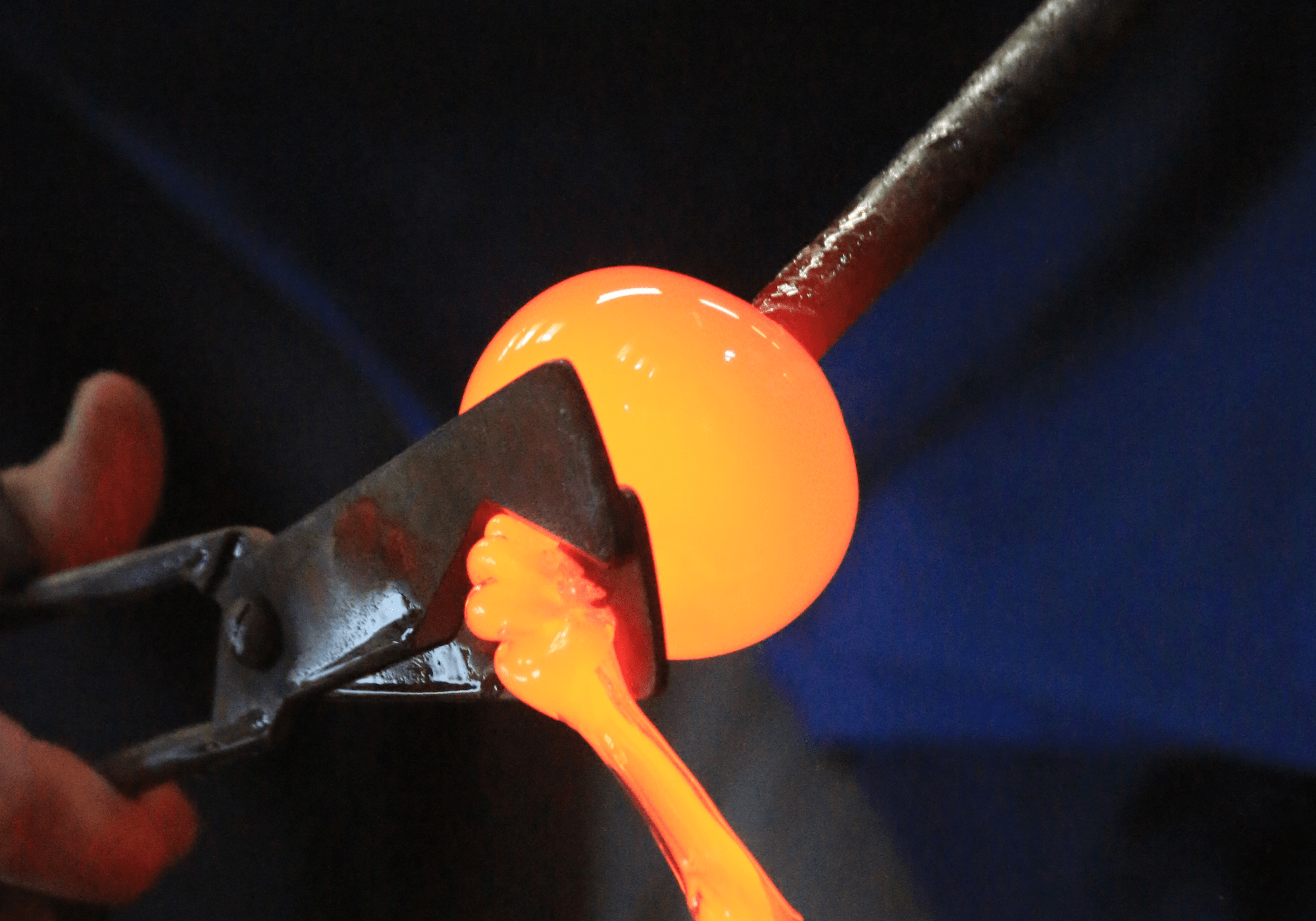

In the melting pots of the glassmakers, the silica sand is transformed by the intense heat of the furnaces. The flames dance gracefully, enveloping the nascent crystal in their fiery embrace.

As specified on the page dedicated to our many skills, the glassmaker first picks at the molten material with his pontil, or cane, then rotates it continuously before breathing life into it, literally.

This is where the magic happens, where the material liquefies, ready to be shaped by the craftsman's hand.

The Shapes' Dance

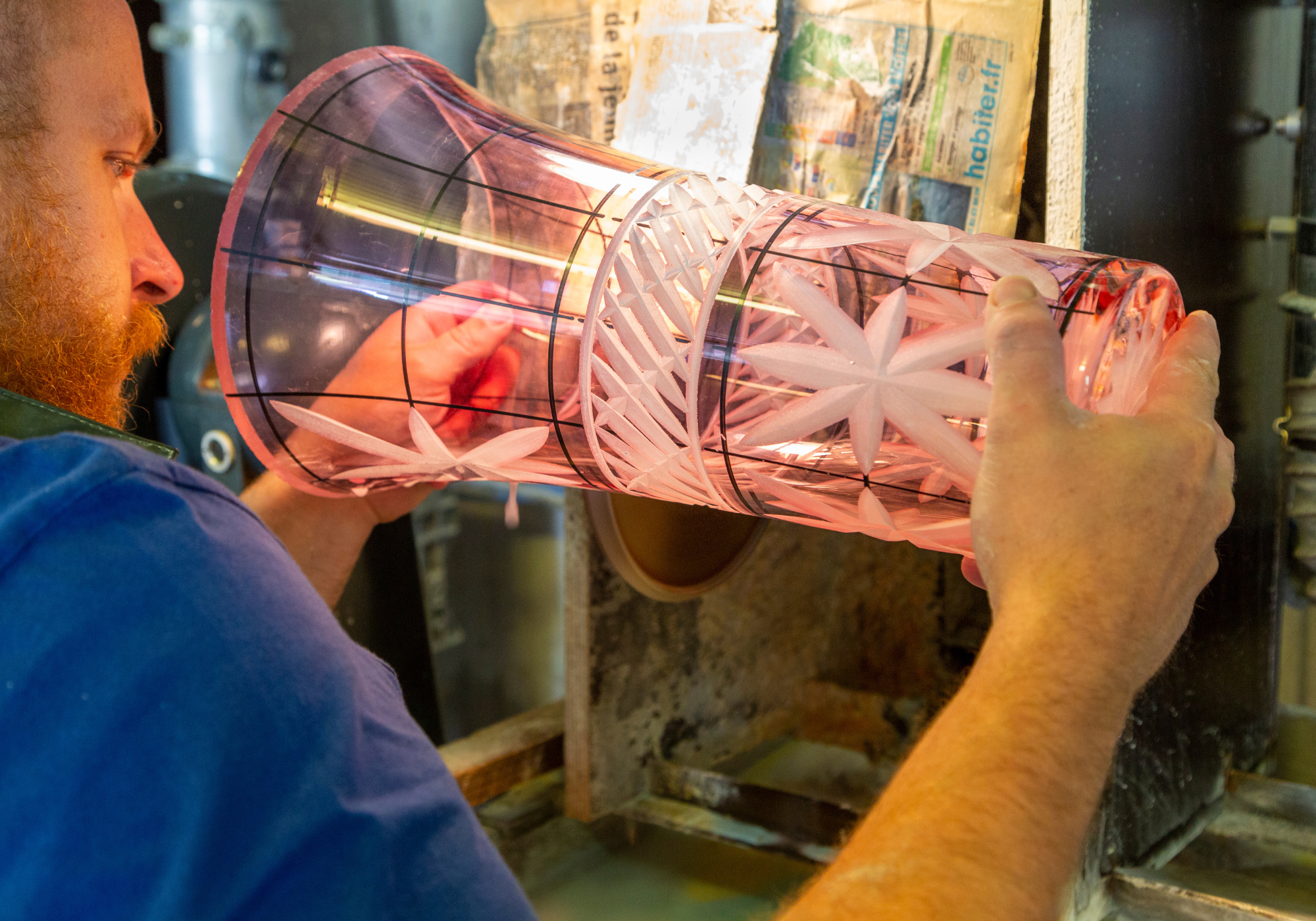

Like an inspired sculptor in front of a block of marble, the tailor brings his creations to life. With skill and precision, each piece is shaped according to the desires of the imagination. The roughing and cutting are carried out using sandstone or diamond millstones rotating at very high speed. A trickle of water mixed with sand flows over the wheel: the water is used to cool the piece; the sand reinforces the work of the wheel. This type of cutting is also known as "cold working". From simple water glasses to real architectural feats, each piece is the fruit of age-old expertise and infinite passion at Cristallerie de Montbronn.

The piece is then polished to restore its original brilliance, using a variety of methods, specified on our expertise page. Depending on the design, the piece will be gilded and finally signed, before being prepared, packed and dispatched.

The final sparkle

After being carefully cut and polished, the crystal finally reveals its true splendour. Each facet reflects the light in a unique way, capturing the brilliance of the sun. This is how these jewels of memory are created, dazzling us with their timeless brilliance.

Throughout the ages, crystal has fascinated mankind with its eternal and mysterious beauty. From its genesis in the bowels of the earth to its final form, each stage of its journey is imbued with poetry and grace. So, whether in a glittering chandelier or a simple stemmed glass, crystal continues to amaze us, reminding us of the poetry that lies in its creation.