Blowing

The creative work is a primordial stage: it is at this precise moment that the first draws of a collection, a design, a new poetry ready to be sung in our workshops are put down on paper.

The magic of crystal is made when the molten material forms a glowing ball, at a temperature of 1200°C (2192°F). The glass craftsmen must then carry out a continuous rotation of the cane in order to obtain a homogeneous form, forming what essentially is crystal. All in all, crystal is one of the most poetic materials there is: a product of the fusion of the purest earth, fine and immaculate sand, offering a perfect refraction of sunlight.

Cristallerie de Montbronn is specialized in the making of custom-made molds, allowing the continuous concrete realization of our new collection designs. The realization of the drawings and prototypes is carried out in our offices, while the manufacturing of the molds is entrusted to a specialist and carried out under a short period of time ; an efficient teamwork for a perfect harmony.

Cutting

The cutting is done cold, when the crystal has been previously blown and the shape of the piece shaped, all done by hand.

The rough outline and cutting are done with sandstone or diamond grindstones, rotating at very high speed. A gentle trickle of precious water, mixed with sand, flows over the grindstone : the water cools the piece down, and the sand reinforces its work.

The pieces made by Cristallerie de Montbronn stand out thanks to a wide variety of crystal cuts, going from the most traditional (diamonds, stars, flat cuts, bevels ...) to the most modern, both in their entity as in their use.

Moreover, this work is carried out with great mastery, sometimes imposing a game of expert meticulousness with the strength of the material.

Freehand cutting gives each piece its unique character.

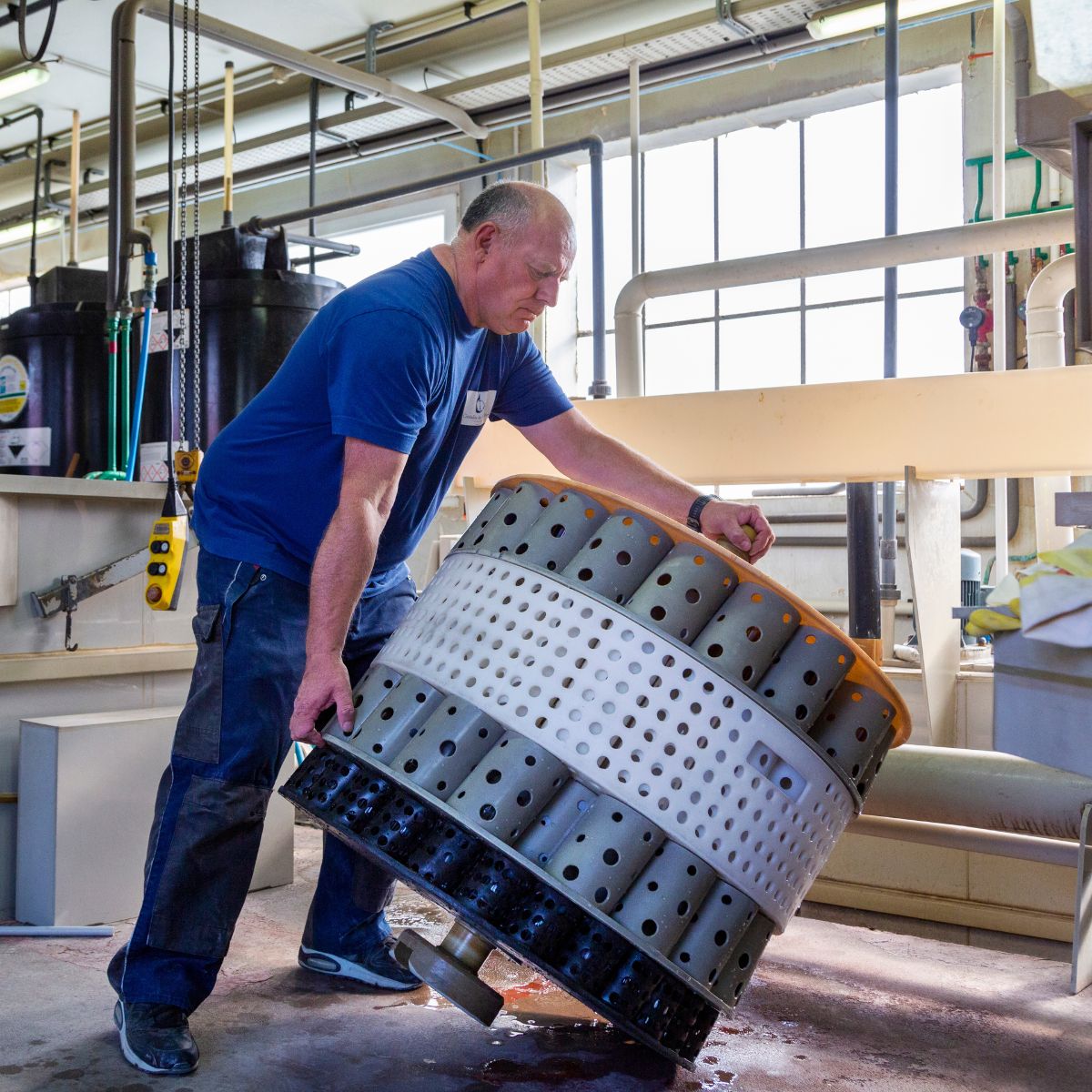

Polishing

Crystal polishing removes all traces of tools and molds from the surface of the piece and gives the material its precious shine and smoothness.

Cristallerie de Montbronn has its own polishing station, left in the hands of our expert in the field, Freddy. In this chemical polishing process, the piece is dipped in a hydrofluoric acid bath. When the acid comes into contact with the crystal, it regains its original shine and gives a clean, sparkling appearance to the material.

Mechanical polishing is also used by Cristallerie de Montbronn. The crystal piece is then polished with a polishing wheel when acid polishing is not appropriate.

Polishing is the intermediate step before gilding and signing.

Gilding

Once the glass has been cut and polished, gilding is the final and most time-consuming step in the creation of a crystal piece. Indeed, gilding requires more than 20 steps on each product to achieve the desired result.

Virginie, a crystal decorator at the Cristallerie de Montbronn, places a decal with the desired design on the glass. The piece is entirely protected so that only the design is visible. A final step is then necessary to allow the design to reveal itself.

The gilding is applied on the crystal with a brush in the embed parts, a work of extreme precision performed by hand.

The piece is then baked to set the gilding, then polished with a precious mineral to make the gold shine.

We are now proud to offer you 5 colors of precious finish: rose gold, matte gold, shiny gold, platinum and black chrome, all detailed on their dedicated page.

Bronze

Working in close collaboration with smelting plants in the Grand Est region, Cristallerie de Montbronn is keen to highlight regional know-how and offers majestic pieces combining crystal and bronze.

The bronze pieces are melted in molds belonging to Cristallerie de Montbronn, made on command and arriving in our workshops in separate pieces.

The welding work is entirely done in our workshops, by our master bronze worker, Denis.

Once the composition of the bronze piece is finished, the skeleton is sent to gilding. The piece is then entirely immersed in a 24-carat gold bath or in a platinum bath for a shiny and ravishing final result.

The assembly of the bronze and the crystal parts is done in our workshops.

The numerous know-how of Cristallerie de Montbronn have been recognized by the prestigious Entreprise du Patrimoine Vivant Label (EPV).

EPV Labelized since 2007

Cristallerie de Montbronn is federated by the Ateliers d'Arts de France, who shines light on French know-how.

Members of the Ateliers d'Art de France since 2019.