Cygnes - Footed bowl

Crystal and bronze footed bowl from the Cygnes collection, available in clear or coloured crystal.

Mouth-blown, hand-cut and assembled in our workshops in Montbronn.

Reference : 570 555

Entreprise du Patrimoine Vivant

- An artisanal company committed to anti-waste, Cristallerie de Montbronn produces to order in order to avoid waste and polluting mass production.

- Each product results from mouth-blown and hand-cut production

- Made to order implies longer manufacturing and delivery times, but ensuring a personalized, precise, and ecological production.

- The average delivery time is between 2 to 8 weeks depending on the state of our stocks.

- For more information, do not hesitate to contact us directly by e-mail public@cristallerie-montbronn.com, via our Chat or by telephone at +33 (0)3 87 96 00 32

We invite you to read our maintenance recommandations to preserve your crystal pieces.

For any purchase made on our website, a repair and polishing service is guaranteed for your items marked by time.

Choose options

Step 1

Blowing

Our crystal factory creates unique pieces, shaped with passion. From drawing to custom moulds, each step is carried out with precision in the process of creating our mouth-blown products.

Know more

Step 2

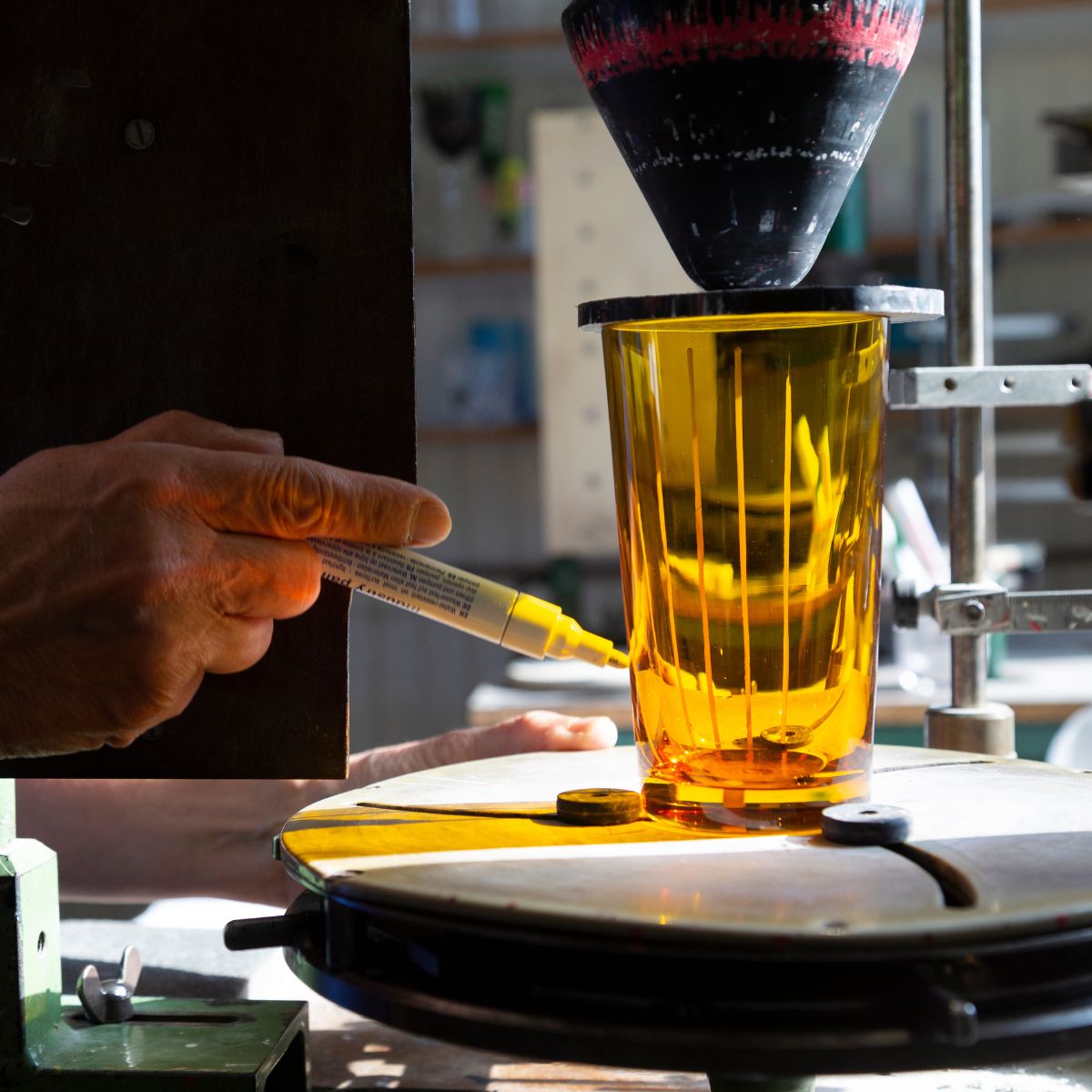

Compassing

Work of extreme precision, compassing prepares the step of the cut. Our expert collaborator accurately traces a regular canvas, serving as a benchmark for the cutter during the cutting process.

Know more

Step 3

Cutting

Freehand cutting gives each piece its unique personality. With master control and meticulousness, our cutters use sandstone or diamond grindstones in order to cut the previously-blown crystal. From traditional to modern designs, Cristallerie de Montbronn offers a great variety of cuts, all realized with master expertise.

Know more

Step 4

Polishing

Crystal polishing removes all traces of tools and molds from the surface of the piece and gives the material its precious shine and smoothness. This step is crucial before gilding and signing.

Know more

Step 5

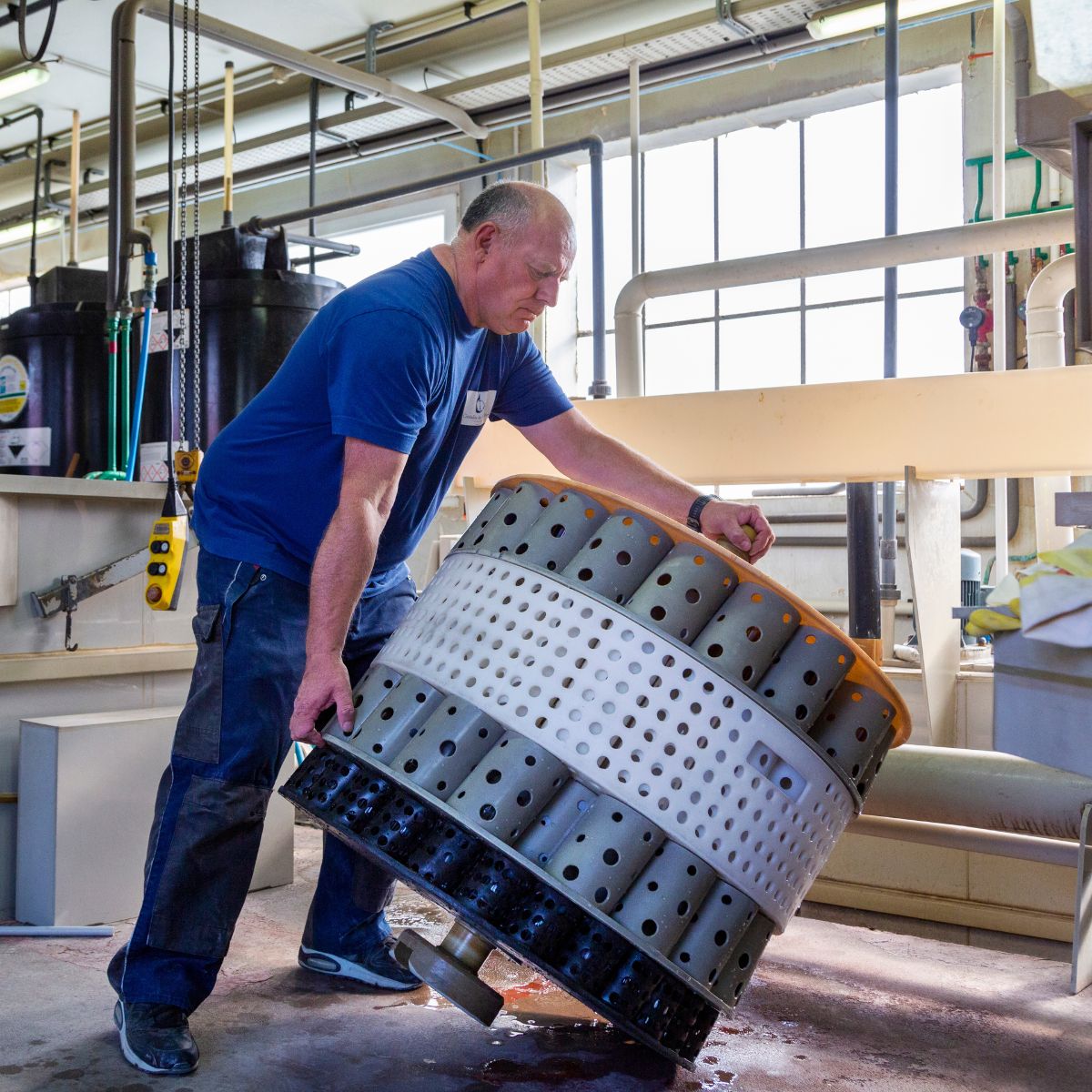

Bronze

The Cristallerie de Montbronn highlights regional know-how by combining crystal and bronze. Our bronze pieces are melted in our moulds, then assembled in our workshops.

We now offer 5 finishes for our bronze parts: shiny gold, matte gold, platinum, black chrome and rose gold.

Know more

Step 6

Signing

After a demanding quality control, each product can be signed Cristallerie de Montbronn, before leaving our workshops carefully packaged in a box in the colours of our House.

Our commitments

Repairs & polishing

As a luxury crystal brand, we are committed to preserving the beauty and quality of our products over time.

That is why we offer a maintenance, repair and polishing service for products that have been chipped, scratched, or tarnished by natural wear.